Nevada distribution center to be consolidated into Indiana campus

Severe conditions seen throughout the UAE, with flooding in Dubai

Reductions part of reorganization announced in November 2023

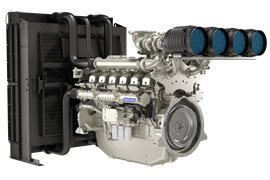

New four-cylinder G-Drive R24 suited for applications in the 20- to 40-kVA range

World’s biggest OEM says AI is evolving at a rapid rate

55 Wrightbus double-deck buses are being rolled out across Limerick

Sponsored Content

See why the compact but mighty John Deere 4.5L Stage V industrial engine was the right solution to power Gunnar Guldbrand A/S’s custom truck solution for horizontal directional drilling customer Eco Drilling.

In this second installment of a three-part series on what makes a facility “state-of-the-art,” we examine a philosophy related to cutting-edge plant floor technology: smart manufacturing.