New four-cylinder G-Drive R24 suited for applications in the 20- to 40-kVA range

World’s biggest OEM says AI is evolving at a rapid rate

55 Wrightbus double-deck buses are being rolled out across Limerick

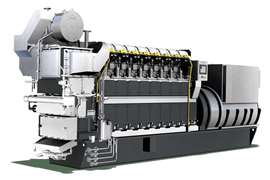

Dual-fuel engines will form part of a diesel-electric propulsion system on board the vessel

Can charge EV truck or bus with large battery capacity at 460 kW within two hours

New Falcon Lifts wheeled electric spider lift is also designed for outside use

Sponsored Content

See why the compact but mighty John Deere 4.5L Stage V industrial engine was the right solution to power Gunnar Guldbrand A/S’s custom truck solution for horizontal directional drilling customer Eco Drilling.

In this second installment of a three-part series on what makes a facility “state-of-the-art,” we examine a philosophy related to cutting-edge plant floor technology: smart manufacturing.