OEM reveals 2023 sales for construction and resource industries, and its highlights of the year

10,000 W gen-set will be composed of a hydrogen fuel cell and a lithium-ion super battery

New solutions increase EV system offerings to support medium- and heavy-duty commercial vehicles

Accelera NMC battery pack to be used for first time in Europe

Sponsored Content

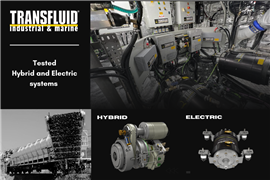

Efficiency in the marine, industrial and railway sectors: electric motors for silent propulsion and cost reduction. Hybrid propulsion Transfluid optimizes energy, costs and emissions. Breakthrough for sustainable and efficient mobility, reducing environmental impactElectric & Hybrid propulsions

In this second installment of a three-part series on what makes a facility “state-of-the-art,” we examine a philosophy related to cutting-edge plant floor technology: smart manufacturing.